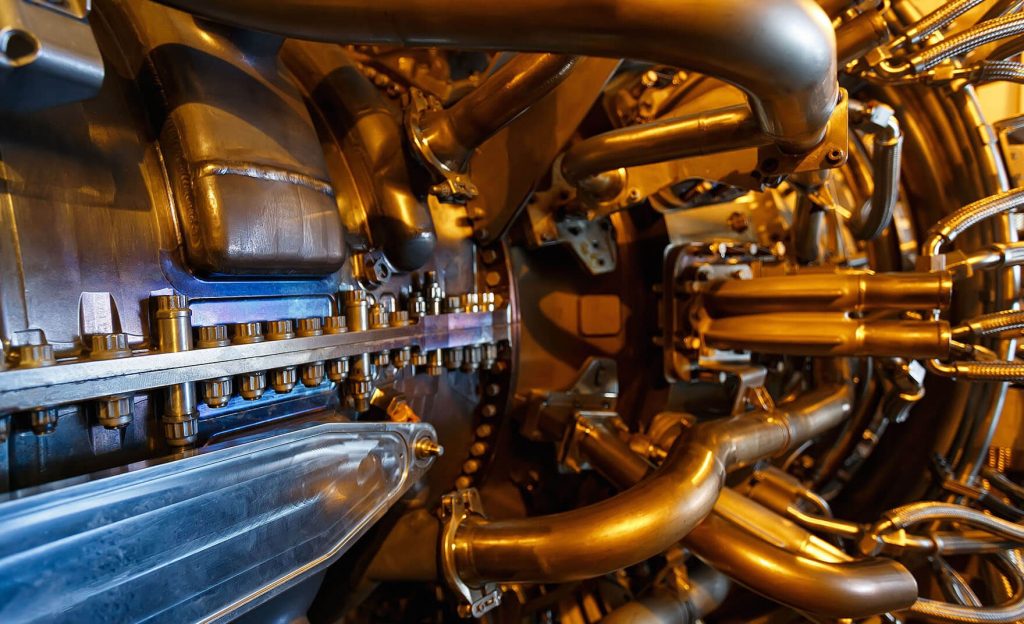

27 Dec What is Turbine Oil Oxidation Stability Test About?

When coming across different types of articles about turbine oil, you might have read “Turbine Oil Oxidation Stability Test”. But what is it all about? The ASTM D943 or commonly known as the Turbine Oil Oxidation Stability Test (TOST), is widely used in the lubrication industry to evaluate the oxidation stability of various industrial lubricants in the presence of water.

Oil Oxidation Stability is a crucial consideration when selecting an industrial lubricant as oxidation will lead to an increase in the oil’s viscosity and will result in varnish and sludge deposits. This oxidation stability is commonly evaluated by the Turbine Oil Oxidation Stability Test.

What is the Purpose of the Turbine Oil Oxidation Stability Test?

Turbine Oil Oxidation Stability Test was first developed by the American Society for Testing and Materials (ASTM) in 1943, with the current method approved in 2004..

TOST was designed to determine or force lubricants to fail by a specific mechanism that relates to extreme conditions such as high temperature, gross water contamination, and substantial air entrainment. Turbine Oil Oxidation Stability Test was designed to evaluate oils under a specific mode of failure.

What Happens During the Test?

As the test starts, each reactant and catalyst is exaggerated. Three (3) milliliters of oil is mixed with 60 ml of water which is equivalent to a mixture with 17% water, heated to 95°C (203°F), and agitated by an oxygen flow, in the presence of iron and copper catalysts. Under these conditions, the lubricant will oxidise or hydrolyse, increasing its acidity or acid number (AN), which is the metric used to measure oxidation stability. The test usually takes one (1) year to complete.

Turbine Oil Oxidation Stability Test (TOST) is a valuable tool in order to indicate oil life for lubricants that are continuously exposed to gross water contaminations, high temperatures, and air entrainment in field service. It has its limitation in determining oil life for oils that are susceptible to other failure modes such as hydraulic oils.

If you are looking for a Turbine Oil distributor in the Philippines, contact us today and we’d be glad to help you!